Dawood, A., Marti Marti, B., Sauret-Jackson, V., & Darwood, A. (2015). 3D printing in dentistry. British dental journal, 219(11), 521–529

Background

As advancements in technology are being made, more frequently these have been utilised and implemented into the dental field. In previous years these had more diagnostic roles in practice, however these technologies have begun to involve clinical and restorative roles in dental practice. The rise of Computer Aided Design and Computer Aided Manufacture (CAD-CAM) has been increasingly used in clinical dental practice, such as in the production of drill guides for dental implants, the production of physical models for prosthodontics, orthodontics and surgery, the manufacture of dental and maxillofacial implants, and the fabrication of copings and frameworks for implant and dental restorations. As these technologies become more readily available in day-to-day clinical practice, the implementation of CAD-CAM in dental settings is something that can be taken advantage of to provide more superior and personalised treatment to patients.

Applications of 3D printing in dentistry and oral and maxillofacial surgery

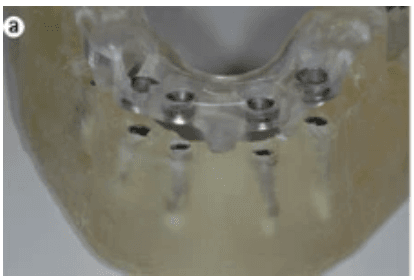

This technology has a wide-variety of current uses in the dental field, and the potential for this disruptive technology to be implemented in patient care is only increasing. The earliest application of 3D printing in surgery is medical modelling, which is the production of an anatomical study model of the patient’s dentition, or craniomaxillofacial structure as seen in Figures 1 and 2. This allows clinicians (such as orthodontists, restorative dentists, oral and maxillofacial surgeons) to review and plan a procedure before it even takes place with an extremely accurate model as a result of CAD-CAM applications.

Figure 1 – Implant drill guide over the 3D printed model

Figure 2 – Pre-empting the position of an osteosynthesis plate using a 3D printed model of a patient’s mandible

CAD-CAM technologies are now able to produce highly intricate and detailed models like in Figure 3. In oral-maxillofacial (OMF) surgery, OMF implants are often simple in form. Computer Aided Manufacturing techniques which include pressing and milling technologies have several advantages, such as reduced post-processing, quick production – all of which can contribute to the management of OMF patients in surgery.

Figure 3 – Cranioplasty and orbital rim implants in titanium fitted to a 3D printed model

Conclusion

It is clear that CAD-CAM technologies – coupled with more advanced intra-oral scanning techniques – have a diverse applicability in a dental setting, particularly for a field experienced in scanning and milling methods – dentists and dental technicians are better prepared than any other public service in the implementation of this. This, however, raises the question of regulators implementing appropriate regulations for safe and effective use. Nevertheless – the advantages are numerous, quick production and post-processing times, as well has personalised and accurate models all are – and will – contribute to better patient outcomes; for healthcare practitioners, that is ultimately the goal.

Research Summary Written By: Omar Almitwally, University of Manchester, BDS1